our services

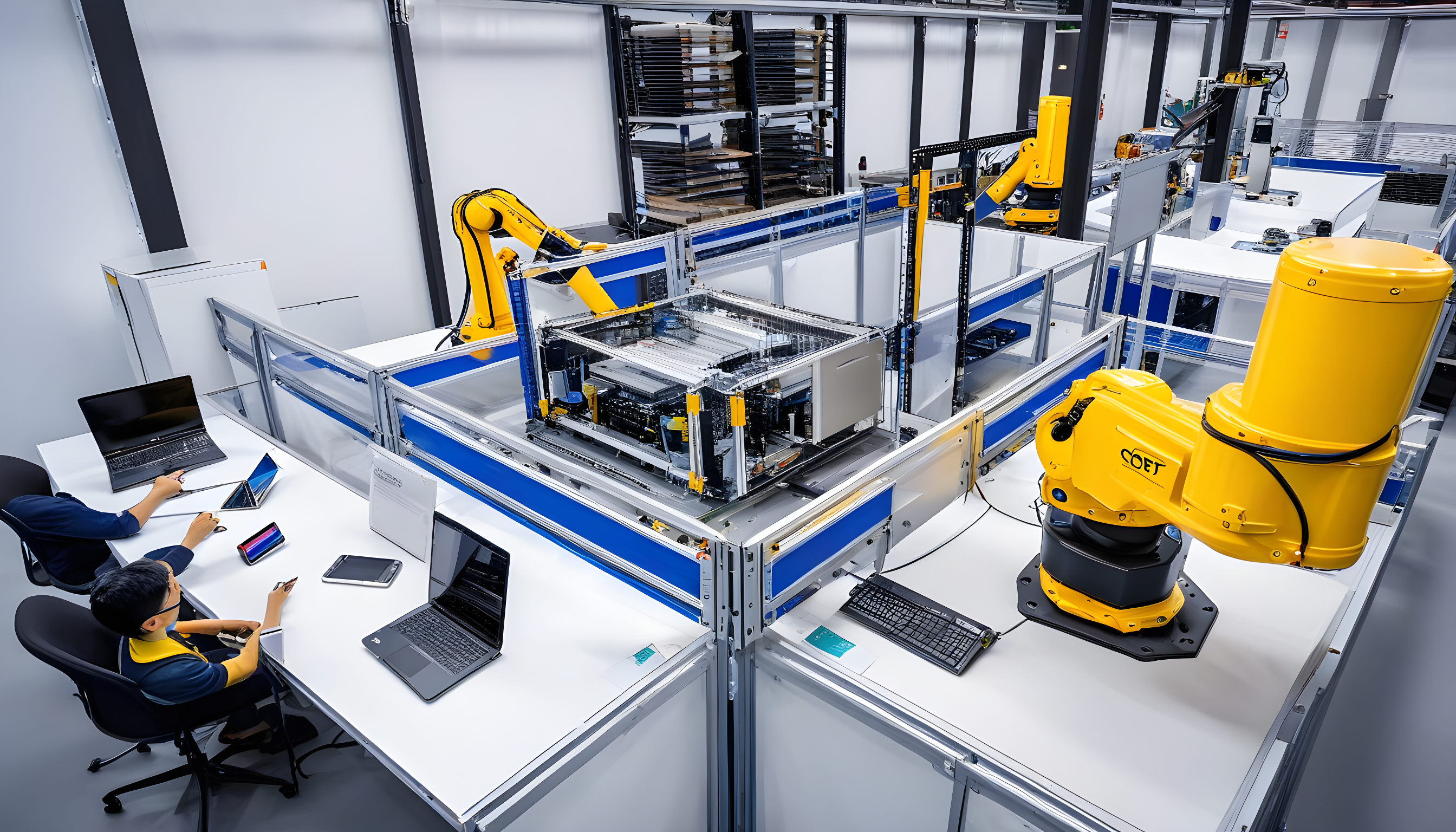

We are at the forefront of driving improvement initiatives in the manufacturing sector. Our specialty lies in guiding our clients through the complete journey of a modernization project, from strategic planning to execution and performance evaluation.

Our team of seasoned professionals is dedicated to optimizing design and manufacturing workflows and processes,

Our services include project management for:

- Process Analysis: We conduct thorough analyses of workflows, cost/labor, feasibility, and productivity to identify areas for improvement.

- BOM & Product Configuration Management: We manage Bill of Materials and product configurations to streamline your operations.

- Lean Best Practices: We implement Lean methodologies to enhance efficiency and eliminate waste.

- Information Systems Deployment: We oversee the deployment and implementation of information systems to modernize your infrastructure.

- Change Management: We manage the transition towards automation, including the deployment of collaborative robots and integration of AI-powered tools.

- Digital Transformation: We drive digital transformation across sales, design, and manufacturing sectors.

- Operations and Logistics Optimization: We optimize operations and logistics for improved performance.

- Marketing & Sales Optimization: We refine marketing and sales strategies to maximize market reach and revenue.

OUR DISTINCTION: Our team’s extensive experience, rigorous approach, and technical expertise sets us apart.

Solutions that help improve ergonomics, increase professional workplace attractiveness and reduce the carbon footprints.